The lower control arm on the twins lacks a crucial component for anyone who lowers, modifies, or wants to track their car; which is the ability to adjust camber. The stock unit does not allow for adjusting camber, which means mechanical grip cannot be maximized or if you lower the vehicle, unwanted suspension geometry may occur. There are two routes to take here; one would be a simple unit that allows adjustment; the other is a complete redesign of the LCA. We decided on the later with the intent to significantly reduce the weight of the component/unsprung weight.

The project began with reverse-engineering the factory component. To do this, we removed the factory component and measured the unit using calipers, straight edge, and a tape measure.

Next up was quantifying the suspension component’s nodes to accurately predict the loads placed on the LCA. At the time we did not have CAD data on the car, so we went about it with a tape measure. Using triangulation for all the suspension component’s nodes, from multiple points, we could accurately place each node within a three dimensional CAD sketch. By using multiple points of constraint, our work was double and triple checked for accuracy as we went along. When a discrepancy arose, a re-measurement would occur until a length from two or three points all lined up. Utilizing the three-dimensional sketch created in CAD, we were able to get X, Y, and Z points for each of the nodes. We later were granted access to OEM CAD data and went back to verify OEM geometry.

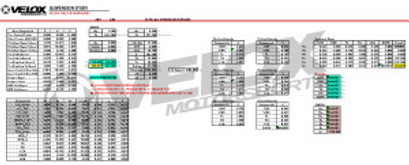

The final step was to build a suspension geometry calculator that would take our inputs and give us usable outputs for FEA (finite element analysis). Inputs were the XYZ coordinates from the previous step and the loads we determine to place on the vehicle. These loads were race conditions, 1.7G lateral acceleration, 0.75G longitudinal acceleration, and 3.5G bump acceleration. In common terms, this is a vehicle with very wide and sticky rubber taking a very hard turn, while accelerating significantly, and hitting a racing curb dead on causing the suspension to compress quickly and significantly. The calculator’s outputs were loads placed on each node of the LCA, in a vector format. Vectors have a magnitude and a direction, so this allows us to apply the loads in the correct direction on the bolt holes.

The next post in this section will go through our design goals, how we went about achieving them and setting up an FEA analysis. Please don’t hesitate to e-mail or comment if you have any questions regarding anything stated in this article.

FT-86 Lower Control Arm Development