Synopsis:

Radiator fans are a necessity for properly cooling vehicles during all conditions. They are a very simple component but are often overlooked and miss-understood. This blog post will go more in-depth with radiator fans; when/where they are beneficial, how they work in the overall cooling stack, common misconceptions, things to look out for, and more. In this blog post, we will be focusing on electric fans as that is what is typically used for sports cars.

When are radiator fans helpful? This is dependent on vehicle and cooling stack thickness, but generally, electric radiator fans are only needed up to 20-30MPH road speed. What can influence this is grill opening, cooling stack thickness, outlet ducting, and the fan’s characteristics. After this speed, airspeed and pressure are sufficient enough to out-flow an electric fan’s capabilities.

How do electric radiator fans operate? Electric radiator fans have a pressure vs. flow curve that governs their performance. This curve is dictated by the motor and the aerodynamics of the blades.

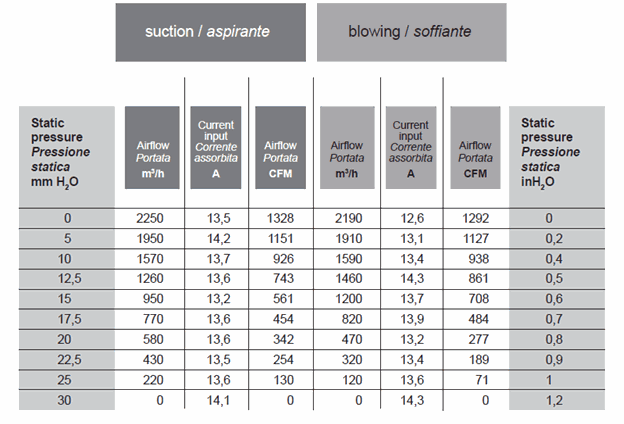

Any manufacturer that states a single flow rate without a pressure reading is trying to sell something. To take this a step further, stating the flow rate of a fan at zero static pressure is completely and utterly useless in understanding the fan’s true performance! A fan’s job is to pull air through something, this something will ultimately create a restriction or a pressure drop. A fan will always have to deal with a restriction. Below is numerical data of a SPAL fan showing what is called, in the cooling industry, a fan curve.

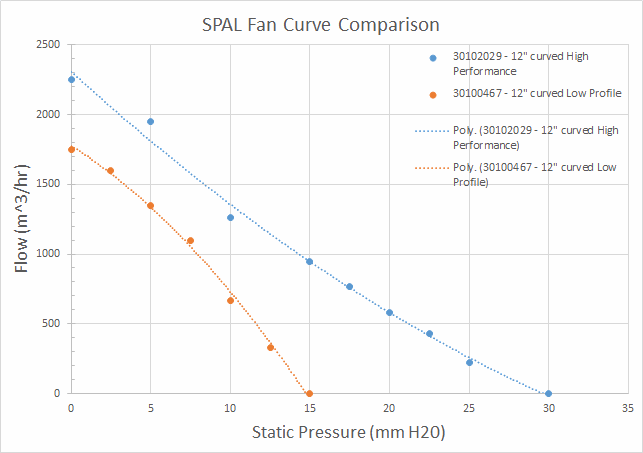

So what is the difference between slim fans and regular fans? Typically the aerodynamics of the blades is very similar if not the same, but the motors are much less powerful. Due to this less powerful motor, the fan cannot pull through high static pressure. Below is this illustrated for the same 12” fan, but one is a slim fan, and one is the high-performance variant. As can be seen, the low profile unit drops off under higher static pressure, significantly. The high-performance unit continues to pull reasonable amounts of airflow even after the low profile unit stalls, pretty impressive.

What is a typical static pressure? A typical radiator core has around 7-15 mm H2O of static pressure when the fans are pulling air through them depending on its thickness. A thicker radiator will inherently have a higher static pressure unless some trickery is done with fin heights and louver details. We’re going to assume standard cores, fin heights, and louver details though as very few core manufacturers have the ability to vary the fin geometry. What compounds this pressure drop is thick charge air coolers, which block airflow further.

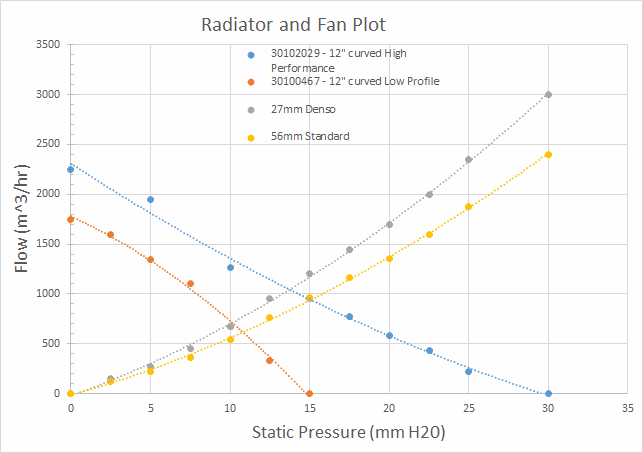

So what does this pressure drop look like and how do I figure out how much airflow my fans can pull through my radiator? That is most certainly a difficult question to answer. We’ve created a graph, and while it is indicative of real-world behavior, it is a made-up scenario for this specific case. Heat rejection, in general, is still a bit of a dark art to most, as there are a lot of factors most people do not consider. Below is a graph of what a 27mm Denso core (what we use in our radiator) would typically flow vs. a given static pressure, and a more standard used 56mm core.

There are some neat things we can learn from this curve.

Low profile fans pull dramatically less airflow through the radiator cores than a high-performance fan.

Looking at the 27mm core, a low profile fan would pull around 650 m3/hr of airflow while a high-performance fan would pull around 1100 m3/hr. That’s a significant difference in airflow and one that will most certainly make an impact on low vehicle speed cooling.

We can clearly see that the 27mm Denso core flows more airflow for a given static pressure. This makes sense, as the core is thinner. From past experience, we know the 27mm outperforms the 56mm core in heat rejection as well, which is pretty impressive given that it is under ½ the thickness.

Major Take-Aways:

Fan ratings at 0 static pressure drop are useless for determining actual operating performance

Low profile fans dramatically reduce cooling at low airspeeds while reducing the size significantly

Fans are truly only beneficial at road speeds under 25-30MPH

As always, thanks for your interest and time!

Radiator Fans - In Depth Explanation and Information