In today’s blog, we dive into a common incorrect perception that a flat underbody is necessary and vital for a rear diffuser to function. We have stated from the beginning that this is not necessary; pointing to SAE articles that have studied this in great detail in both CFD and wind tunnels. We have now gone through a very in-depth study of our own and will be publishing the data below. First, we will detail out the model used, then the CFD setup, the numerical data, and then CFD post-processing photos. Strap in, it is about to get pretty interesting with information not from hear-say, but from legitimate testing using state of the art CAD and analysis software.

Vehicle Model:

For the vehicle model used; we chose the DrivAer model; which is a generic car model developed at the Institute of Aerodynamics and Fluid Mechanics at the Technische Universitat Munchen. We used this model because of its extensive CFD and wind tunnel testing to compare results to our CFD (read validation ability). The CAD is directly from the university. We chose the notch rear section as it represents most cars that track the best. We added a basic diffuser design for the test. The diffuser performance could be increased if we spent time optimizing the part, but this gives an insight into how a basic diffuser can help the performance of the vehicle whether the car has a dirty or smooth floor. There are four total analyses being performed here, No Diffuser Dirty Floor, No Diffuser Flat Floor, Diffuser Dirty Floor, and Diffuser Flat Floor.

CFD Setup:

All the CAD work was performed by Siemens NX. CFD model preparation and wind tunnel creation were tweaked and generated in ANSYS Spaceclaim. Mesh creation and solving were performed by ANSYS Fluent. Post-processing images for this study were in Paraview. The model was run as a full-scale model; we did not utilize a symmetrical plane down the center for this study. Rotating wheels were used which is standard for us. The maximum mesh skewness was 0.86 in all model setups, which is considered very good for this type of analysis. The average mesh was 40 million cells using Fluent’s poly-hex core mesh.

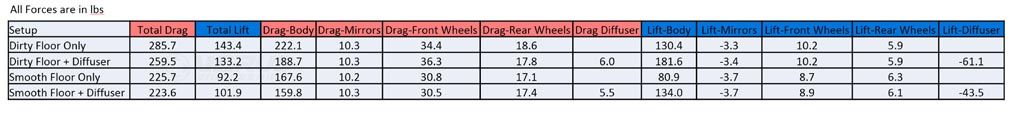

Numerical Data Overview:

Drag Overview

The highest drag setup is the No Diffuser Dirty Floor model. The lowest drag is the model with the Diffuser Flat Floor. In both the Flat Floor and Dirty Floor, the diffuser decreased drag in both models. The diffuser was actually more successful at decreasing drag with the dirty floor.

Lift Overview

For lift, a lower value is better if we want to start to make downforce. Keep in mind, the DrivAer model creates lift, like nearly all factory vehicles. The downforce increase from adding a diffuser to a dirty floor model was 9 lbs on the overall vehicle, while the downforce on the diffuser itself was 61 lbs. This is because the diffuser affects other areas of the car. On the smooth underbody, we actually lost downforce with the diffuser. Without a doubt, we could get an increase in downforce on the diffuser, flat floor model over the flat floor only model with a few quick tweaks to the diffuser though.

Numerical Data Conclusion

The diffuser improved performance on the dirty floor model in both drag AND lift and did not need a flat floor to function. However, we have seen it stated hundreds of times that a flat floor is exclusively necessary to run a diffuser. That is 100% false and should not be believed as we have proven. SAE article 2012-01-0168 has detailed Cp plots on the underside of the DrivAer model if you are interested in Cp differences of dirty and smooth underbody as that is out of the scope of this blog. As we have stated multiple times, the only way to know if an aerodynamic device is working is to do some sort of testing. That testing can be a wind tunnel, CFD (read accurate CFD software and knowledgeable CFD practitioner; there are programs that should not be used for CFD), or using proper data acquisition systems on track. We personally believe CFD is the best route to take as it offers the most benefits to our needs.

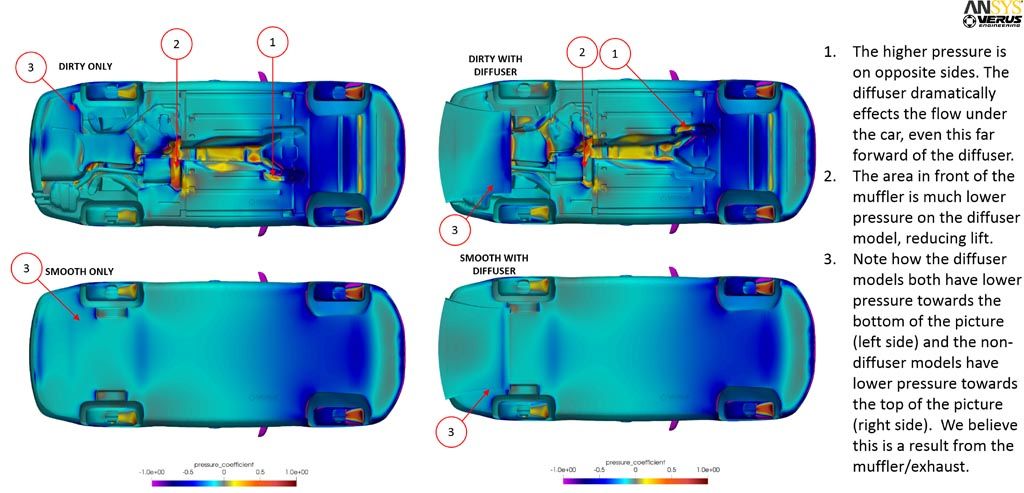

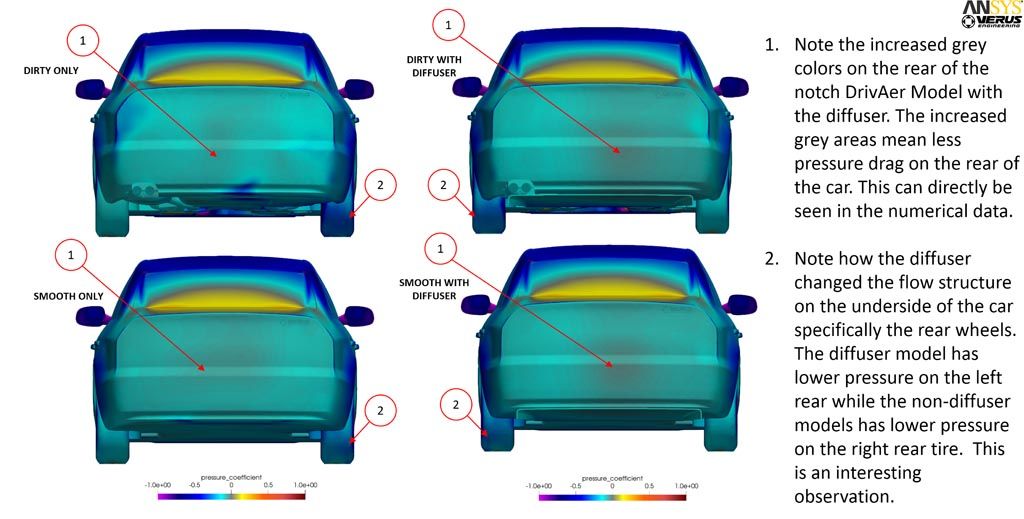

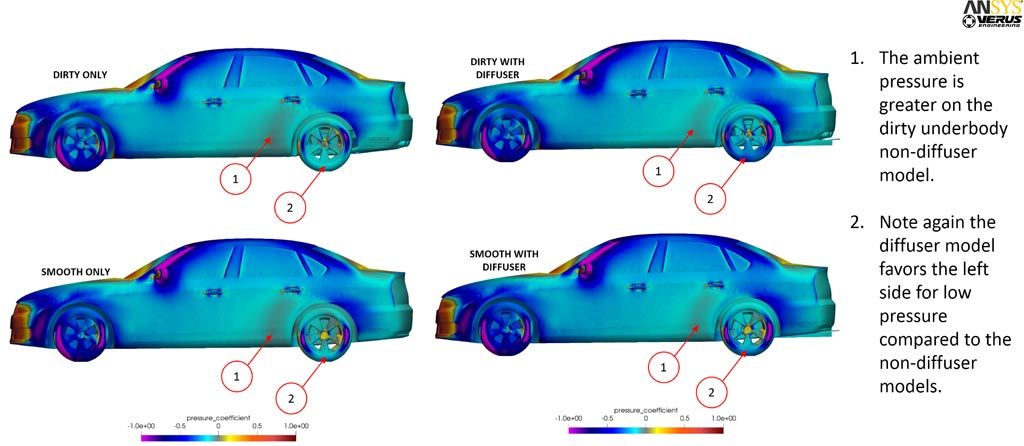

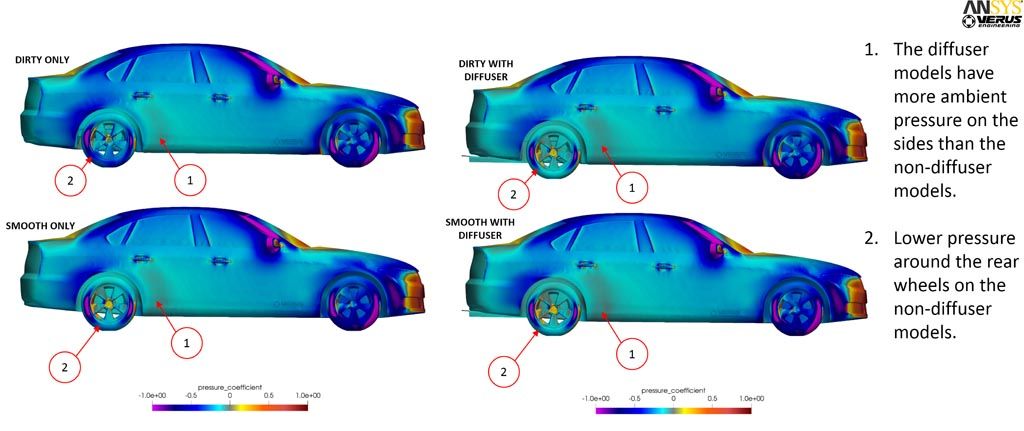

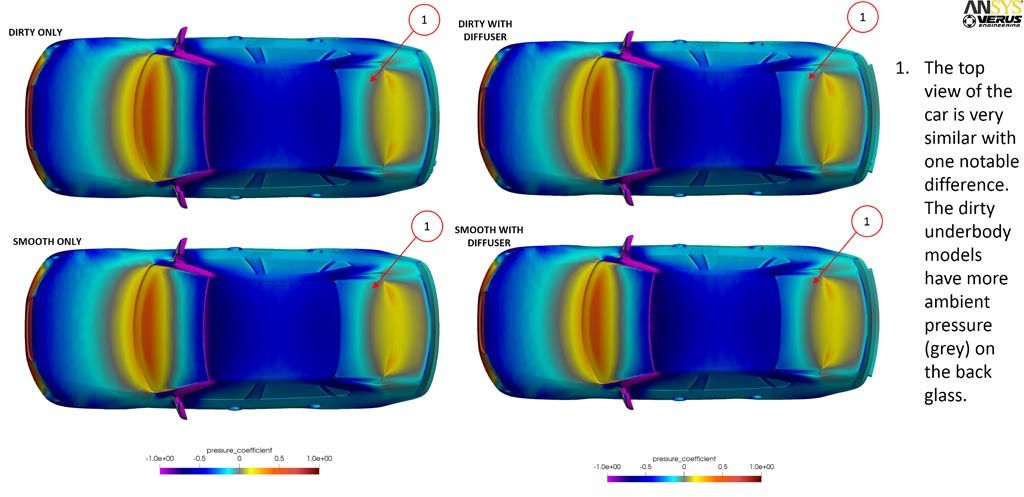

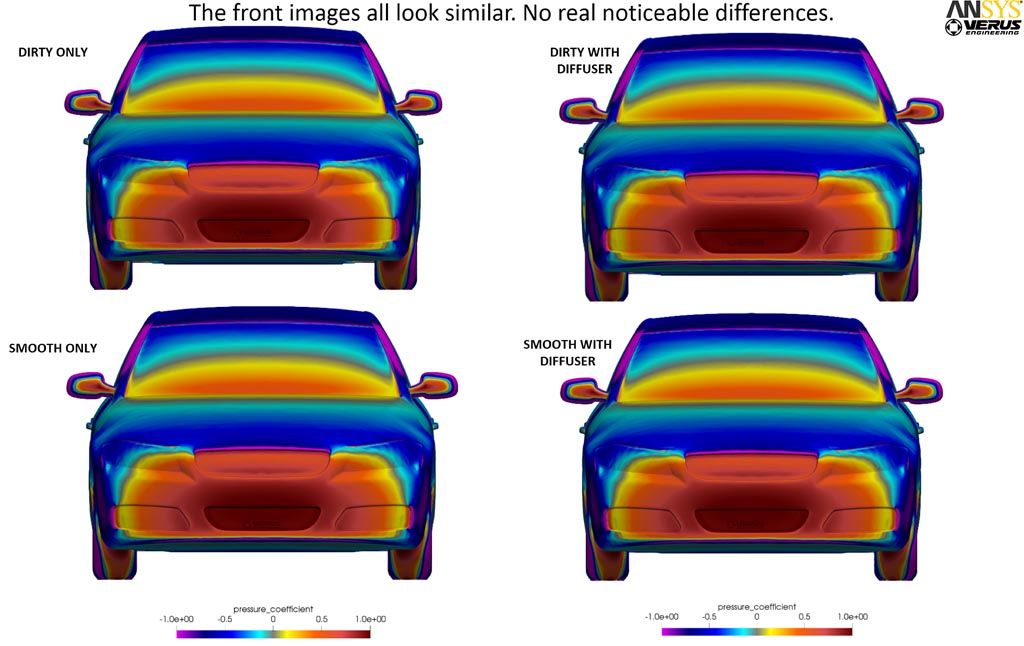

CFD Post Processing Images:

All images shown below have a coefficient of pressure plot on the surface. Cool colors, such as blue and purple, are areas of low pressure. Warm colors, like yellow, orange, and red, are areas of high pressure. Gray is ambient pressure and has no effect on the performance. Low pressure on the underbody is good for performance as that improves downforce, or reduces lift in this case. High pressure on the underbody is bad. Below, we have pointed out multiple images of interest with arrows for your viewing pleasure.

Ultimately we have detailed out and proven that flat floors are not necessary for diffusers to function and improve vehicle performance. There are published SAE articles as well as other published educational papers detailing different underbody details and diffuser designs that are also available on similar topics. Aerodynamics are not intuitive and at times counter-intuitive. Analysis work and validation are both necessary to ensure an added component actually improves performance. Hear-say does not belong in aerodynamics.

Is a Flat Underbody Necessary for a Rear Diffuser to Function?